-

-

First, an update on the project. This is the Beithe shawlette that I made for my friend Amy out of the Greenwood Fibers Grapevine.

She said that she liked it well enough that she wanted to wear it to bed! I’d say it was a successful project.

But my post is about stuff from my stash. I have a lot of fiber and handspun in my stash. Some of it can easily be 20 years old. I have a good memory for most of it. But I can’t remember what type of wool this is. I do remember that it’s dyed with Rit dye.

As you can see, it combs up nice. It might be Rambouillet. It’s crimpy, with about a 3 inch long staple. I’m sure I’ll think of a use for it. I should at least weigh it and find out how much of it I have. I’ll have a lot of waste when I comb it though.

-

I have been busy knitting AND spinning. So let’s do some recent stuff.

Spinning singles from Grapevine

Spinning singles from GrapevineSock yarn from Twilight, using my new Enid Ashcroft Midge in Tulipwood

Another spinner on Ravelry has this same stuff! She says hers was labeled as merino. It sure feels like rayon to me. I guess I’ll know more when I wash it.

It’s made from pine and processed a certain way to make it translucent!

It’s beautiful work by Lon’s wood turning teacher, Howard.

Let’s have one more picture of that EA Midge!

This is the Milk Run shawl, done up in natural colored wools. This is almost all spindle spun. Most of this yarn has been kicking around in bins for a long time now. I really like this shawl.

And that’s it for today!

-

I posted this on the Jenkins forum, but thought I’d post it here too. I did a sampling study, which is pretty unusual for me. I noticed that the yarn spun and plied on my Turkish spindles had a puffiness that I hadn’t seen before. I wanted to do a test, with spindles of similar weight and fiber prepared in the same way. So here’s my test, starting with the first group of spindles:

The high whorls are:

The custom is a tiny bit lighter than the boat anchor Turk, but close.

The fiber is a Corriedale/Romney, combed on Viking combs from roughly the same area of the fleece. I tried to use the same draw on both samples. I did give the Turks an extra spin, during the original spinning and also on the plying. The high whorls didn’t need that.

Here are the results;

Second picture of the samples:

I think you can really see the difference here.

I have not counted twists per inch and it’s likely that the Turks are putting less twist into the fiber. The interesting thing is that you could choose to use Turkish spindles to deliberately get a puffier yarn, even out of fibers that are a bit on the coarse side. But, if you are doing socks, you might want to go with high whorls. That would give you a longer wearing yarn.

If anyone else tries this, please let me know how it turns out! I think I’d like to try it with carded fiber too. I’ve been spinning a long time, but there are still new things to be learned.

-

I realize I am linking to old posts on Abby’s blog again. But here is another interesting one: Should everyone spin? And while I do agree with this one, it concerns me that the thing most spinners spin is prepared fiber. I’m not sure that it does you a lot of good to know how to spin when that supply of fiber dries up. Knowing how to process a fleece from scratch is part and parcel of spinning.

I finally have taken out all of the bins of fiber in storage. I found one more fleece to wash, now drying. There’s a lot of fiber that’s already been spun. I found more cotton roving. I have my office now full of bins and fleece, roving and yarn everywhere.

And I bought this:

Lovely stuff and I look forward to spinning it (along with my ongoing combed fleece project.)

Lovely stuff and I look forward to spinning it (along with my ongoing combed fleece project.) -

I can’t believe I haven’t posted about Black Sheep. I have so many pictures of sheep, goats and spindles. I picked up a Jenkins Lark.

I have not been a fan of Turkish spindles.All the ones I’ve tried have been bulky and wobbly. This is a most elegant spindle, lightweight and fast. It’s perfectly balanced. I looked at the kuchulus, which are even tinier. I will get one of those at some point, but they are in high demand. And I’d like an Aegean spindle as well. And another Lark in light colored wood. That should be enough!

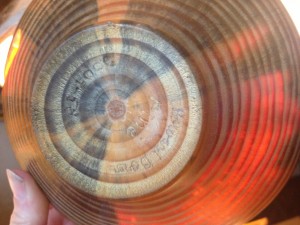

Lon has been taking wood turning lessons. He plans to learn how to make spindles, which will help with my addiction. His first attempt is a copy of one of my Russian spindles:

It’s a good start. I’d like to have a thinner shaft, so we’ll try that on the next one. He’s working with some Eastern maple right now, but we do have a few exotic woods to play with. His instructor is finding this interesting. He made me a set of three support spindle bowls out of maple burl.

And, it’s Tour De Fleece, which I’m doing for the first time. I’m spinning cotton on my Akhas for the Support Spindlers group. I had to trade off with a few other projects over the holiday weekend.

-

This is likely that basic roving that Woodland Woolworks used to sell. I dyed it with Landscape Midnight Blue, the same time that I did the Shipwrecked Shawl. Lon wants a watch cap and I plan to use this for the project. I’m thinking about a 3 ply yarn.

-

I have been thinking about sending off some of my fleeces to be processed. I think I have 11 or 12 of them, plus the 60 pounds of free wool from Craigslist. I worked up a bit of the free wool and I am now thinking about putting that away for awhile. But I do have some nice wool, mostly bought at Black Sheep, that I would like to work up. I have some time for spinning, but I don’t seem to have a lot of time for fiber prep. Back in the day, I did this and had a lot of nice bumps of roving to work from. I love carding and combing my own fleece, but I’ve got to be realistic about this.

To get started, I brought home a shetland fleece I bought in 2007 that still needs to be washed. I’m going to wash it and let it start drying. Then I’ll start bringing home the other unwashed fleeces. All this wool has been in storage for so long. When Jeffrey and I moved to Stabler, I had it stored then. It’s been in storage since I’ve been in Vancouver. I want to make some nice, long lasting sweaters and shawls. I would much rather work with my own fiber than with commercial yarns.

Spindlitis

spinning on the go